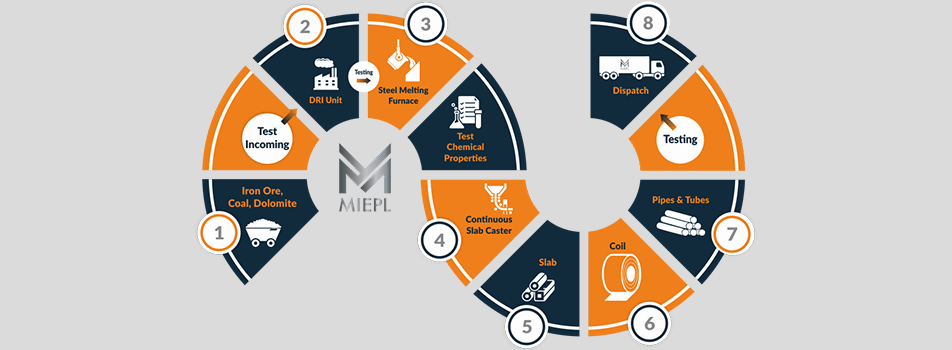

Mines to Mills Integrated Steel Plant

The reason for our superior quality products and service can be attributed to the fact that we have a forward and backward, Mines to Mills integrated steel plant. This ensures that we have complete control over the entire process to achieve physical properties and chemical compositions to surpass BIS standards to manufacture merit quality steel. Having an integrated steel plant also ensures that we have complete control over quality, costs and timely delivery.

MIEPL is produced through a combination of superior processes in our state-of-the-art integrated steel plant. The steel for MIEPL is produced through primary steel making route, using iron ore. It is subsequently processed through the furnace and the virgin steel is refined to the fullest extent and continuously cast into billets.

The resultant virgin steel is of superior quality containing no harmful ingredients and ensures the desired and consistent properties in the Pipes. Cast billets are hot rolled in fully automated Pipe mills equipped with controlled process monitoring devices to ensure uniform properties in each Pipes. All our Pipe mills are fully modernized with latest Pipe technologies employing state-of-the-art tungsten carbide rolls in place of conventional steel rolls, which ensure excellent dimensional tolerance and surface finish.

Hence, the resultant steel has a fine finish, higher strength and superior quality.