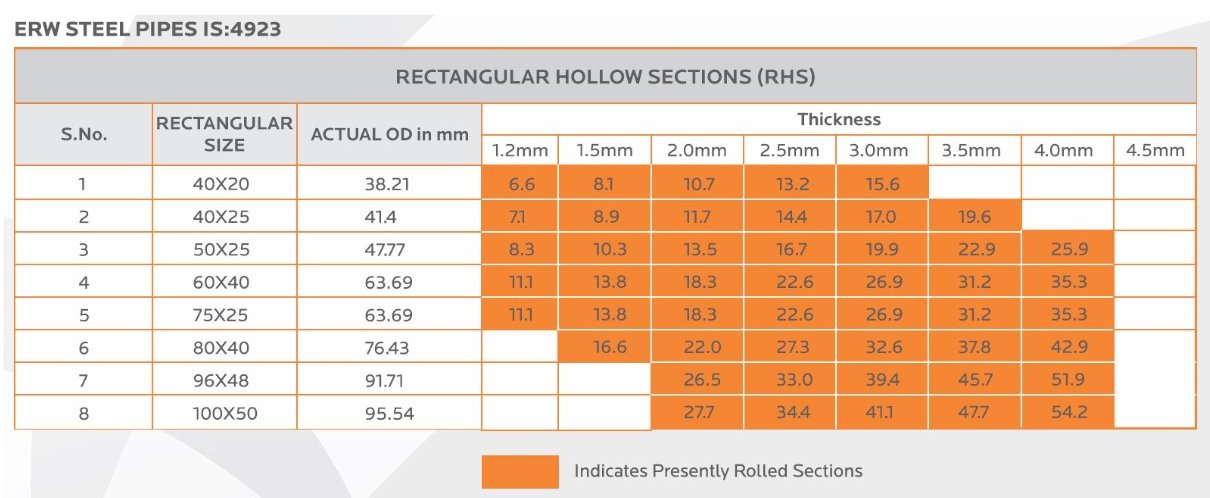

Details of RHS (Rectangular Hollow Sections) :

- Available in different size and thickness

- Customized as per the requirement

- Demanded in structural applications and furniture industries

- Offered at very reasonable prices

- Optimum quality steel components and sophisticated techniques

Features of RHS (Rectangular Hollow Sections) :

- Dimensional accuracy

- Easy fitting

- Longer working life

- Premium quality

- Robust construction

Applications:

- Tyres Industries

- Textile & Spinning Industries

- Sugar mills & distilleries

- Sugar Industries

- Steel plants

- Space & Defence Industries

- Shipbuilding & Repairs

- Roofing Structures

- Refineries

- Racks And Panels

- Pharma Industries

- Petrochemical industry

- Paper & Pulp Industries

- Oil & Gas Industries

- Nuclear, Thermal & Power Plants

- Mining Industries

- Iron & Steel Industries

- Highway / Roadways Signages And Sign Boards

- Gym And Health Care

- Food Industries

- Indian Railways

- Decorative (pergolas + Pillars)

- Construction Industry

- Chemical & Fertilizer Plants

- Cement pumps

- Cement Industry

- Breweries & Beverage Industries

- Boiler Industries

- Automobile Industries

- Aluminum Industry

- Air Conditioning Industry

General Applications :

- Industrial Sheds

- Steel Furniture

- Bridges

- Low cost Steel Housing

- Towers

- Airports

- Tripper/Trailer body

- Bus Body Structures

- Cranes

- Material Storage Racks

- Road Dividers

- Railway Wagon / Coaches

- Hoardings

- Machine Components & Frames

- Pre-fabricated House

- Automobile Chassis

RHS Hollow Section Pipes :

Manufactured using finest quality of steel and Rectangular Pipes are extensively used in welded steel frames which experience loads from multiple directions. The shapes of pipes suit multiple axis loading with having uniform geometry along with two or more cross section axes. This enhances the uniform strength of these pipes, making them better choice for columns.

These are manufactured through the process where flat steel plate is slowly changed in shape to achieve round where the edges are presented to weld. Then, the edges are welded together to form the master tube. This master tube, which is also referred as mother tube goes through a sequence of shaping stands, which form the final square or rectangular shape.